Rubber and polyurethane Pu products

The supply of a rubber and PU roller, wheel and roller coating is not standard. It is tailor-made, tailored to very specific wishes and requirements.

Specific adaptation

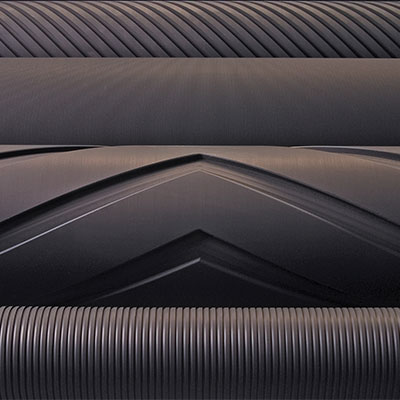

Hardness, wear resistance, oils, solvents, chemicals, high or low temperatures, and of course the intended use are factors that determine the choice of the most suitable coating material. In addition, there are requirements, especially in the food industry (FDA), which may influence the choice of the rubber to be used.

Measurement protocol

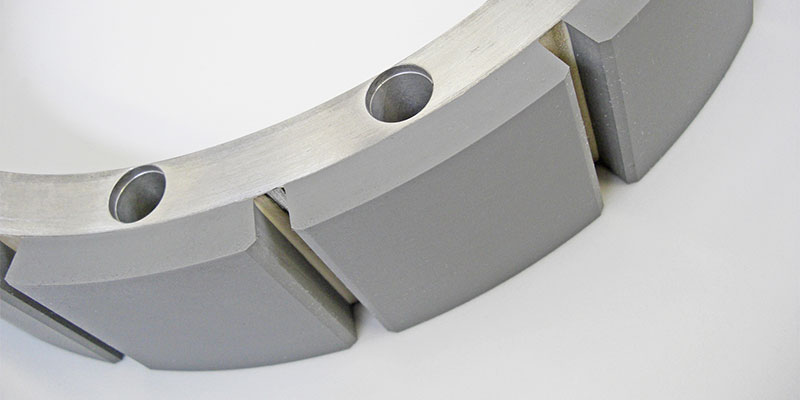

We can produce technical rubber and PU molded articles up to a size of 1500 x 1500 mm.

With our pressing batteries we can produce many types and sizes of technical rubber molds. We use a mold that we can make for you with specialized mold makers. Small and large series of technical molded rubber parts, manufactured to your specifications. With our own rubber qualities, the material can be given different properties in terms of hardness, color, durability, etc. This makes the possibilities almost endless.

Rubber grades

With many self-developed rubber qualities, we deliver customization of small and large series. Various parameters, such as chemical resistance, heat resistance or electrical conductivity as well as low wear, are of decisive importance for selecting the right rubber quality. We help you to determine the optimum quality for your production process. Continuous in-house and further development of compound compounds – tailored to your requirements – can also become a decisive competitive advantage for you.